GUM & RESIN

Lacquer Sap

Product code: SONTA

Net weight: 25kg

Price: Contact

Commercial name: Urushi, Natural lacquer, varnish resin, Japan Sumac, Japan Wax

Botanical Name: Rhus Succedanea

Botanical Name: Rhus Succedanea

Origin country: Vietnam

Extraction: Virgin/Unrefined

Shelf Life: Minimum of 5yrs

Product Classification: Wild Harvested;Naturally Organic;

INCI Name: Rhus verniciflua resin

CAS Number: 8001-39-6

Package: 30 - 50 - 180 kgs/drum

About lacquer tree

Natural lacquer, varnish resin is one of humankind’s oldest materials. In the Stone Age, over 9,000 years ago, people discovered the adhesive and protective properties of the sap of the lacquer tree, and used it in the making of spears and arrows, and to strengthen and protect utensils and other objects. It is still used today by people in East Asia to protect and decorate plates, bowls and ornaments.

About lacquer tree

Natural lacquer, varnish resin is one of humankind’s oldest materials. In the Stone Age, over 9,000 years ago, people discovered the adhesive and protective properties of the sap of the lacquer tree, and used it in the making of spears and arrows, and to strengthen and protect utensils and other objects. It is still used today by people in East Asia to protect and decorate plates, bowls and ornaments.

In the past, in Vietnam, China, Korea, Tibet, Myanmar, Thailand, Cambodia and Laos natural lacquer was used extensively in the decorating temples, creating temple art, and making Buddhist images. Today, in many parts of East Asia, natural lacquer is still used in the production of tableware and utensils for everyday use as well as in creating urushi artwork. It is also used in the restoration of lacquerware and temple interiors.

Natural lacquer is the purified sap of the lacquer tree. The scientific name of the tree used in Vietnam is Rhus Succedanea (Toxicodendron Succedanea). It is native to Vietnam, China, Korea, Japan. The sap of this tree contains a resin, which when exposed to moisture and air, polymerizes and becomes a very hard, durable, plastic-like substance—lacquer! Lacquer is, in fact, a natural plastic.

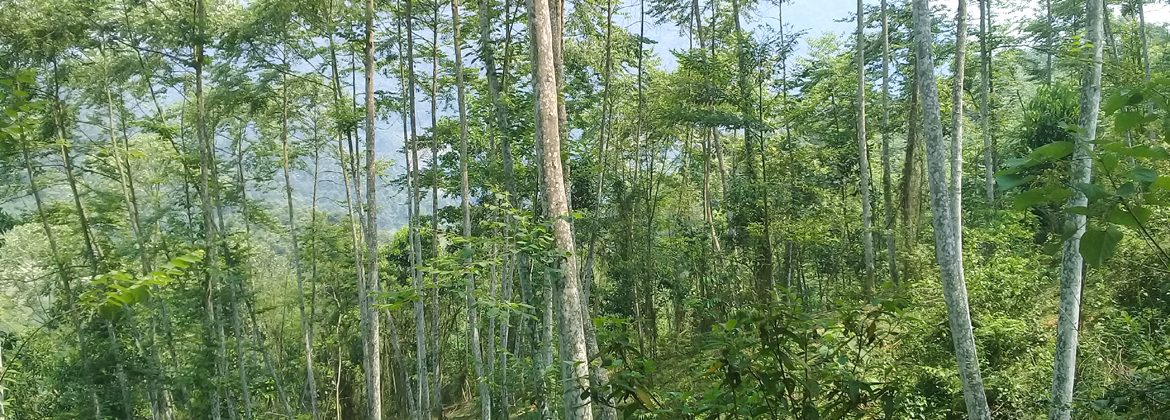

In Vietnam, there are lacquer tree plantations in Phu Tho, Hoa Binh, Lao Cai, Tuyen Quang where the sap is still collected. Once planted urushi can be collected for about 10 to 15 years. Urushi is collected from May to October. The raw lacquer is then filtered to remove impurities. It is then further refined. First by removing moisture and then by stirring the liquid to create a fine emulsion. The active component is “urushiol”, which when exposed to moisture and air, polymerizes and hardens (it does not actually "dry"). Constant temperature and humidity is required for it to harden uniformly, so urushi work is often "dried" in special dust free chambers. Once hardened, urushi is resistant to alkali, acid, and heat.

By adding various natural pigments, lacquer can be colored―black, red, brown, or yellow.